Technicial Specifications

Generator Set Specifications

Engine Specifications

Generator Set Dimensions

| Standby Rating | 4000(no fan)/3900 kVA |

| Prime Power Rating | 3600(no fan)/3500 kVA |

| Emissions/Fuel Strategy | Low Fuel, Low Emissions |

| Voltage | 400 to 11000 Volts |

| Frequency | 50 Hz |

| Speed | 1500 RPM |

| Duty Cycle | Standby, Mission Critical, Prime, Continuous |

| Maximum Rating | 4000 kVA |

| Minimum Rating | 3150 kVA |

| Engine Model | C175-20 SCAC, V-20, 4-Stroke Water-Cooled Diesel |

| Bore | 175 mm |

| Stroke | 220 mm |

| Displacement | 105.8 l |

| Compression Ratio | 15.3:1 |

| Aspiration | Turbo Aftercooled |

| Fuel System | Common Rail |

| Governor Type | ADEM� A4 |

| Length - Minimum | 6711 mm |

| Length - Maximum | 8402 mm |

| Width - Minimum | 2162 mm |

| Width - Maximum | 3247 mm |

| Height - Minimum | 2224 mm |

| Height - Maximum | 3827 mm |

| Dry Weight - Genset (minimum) | 25000 kg |

| Dry Weight - Genset (maximum) | 30000 kg |

Advantages and Features

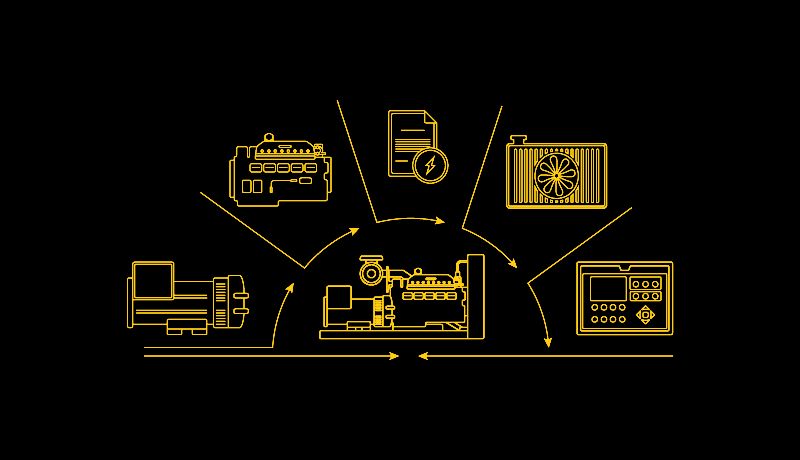

Cat Generator Set Package

- Cat generator set packages have been fully prototype tested

- Accepts 100% block load in one step and meets NFPA 110 loading requirements

- Conform to ISO 8528-5 steady state and transient response requirements

Cat Diesel Engine

- Reliable, rugged, durable design

- Field-proven in thousands of applications worldwide

- Four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight

SR5 Alternator

- Superior motor starting capability minimizes need for oversizing alternator

- Designed to match performance and output characteristics of Cat diesel engines

- Robust Class H insulation

Cat ECS Control Panel

- User-friendly interface and navigation

- Scalable system to meet a wide range of installation requirement

- Expansion modules and site-specific programming for specific customer requirements

Cooling System

- Designed to operate in standard ambient temperatures up to 50°C (122°F)

- Contact your Cat Dealer for specific ambient and altitude capabilities

Certifications

- EU Declaration of Conformity

- EU Declaration of Incorporation

- Eurasian Conformity (EAC)

- IBC seismic certification

One Safe Source

- Components used in the generator set are selected at the design stage to provide optimum package performance

- The generator set is fully assembled at a Caterpillar facility following our quality guidelines

- Each generator set package is tested before leaving the Caterpillar facility

- Cat product support, including dealer service, parts and warranty covers the entire Cat power system

Standard Equipment

-

Air Inlet

- 4 x Single element canister air cleaners with service indicator(s).

-

Control Panel

- Engine cycle crank

- Oil pressure (psi, kPa or bar)

- Digital Indicators

- Coolant temperature

- Environmental sealed front face

- Frequency (Hz)

- True RMS AC metering, 3-phase, +/-2% accuracy

- Text alarm/event descriptions

- Low coolant level

- Volts (L-L & L-N)

- Auto/start/stop control

- Warning/shutdown Indicators:

- Emergency stop pushbutton

- Engine cool-down timer

- DC volts

- High coolant temperature

- Operating hours

- Low oil pressure

- Cat ECS 100

- Amps (per phase & average)

- 4 Programmable relay Inputs

- Alarm acknowledge

- 4 Programmable relay output

- Failure to start (overcrank)

- Overspeed

- Lamp test

- 24 Volt DC operation

- Wall mounted controls

- RPM

-

Cooling System

- SCAC cooling

- Coolant sensors

- JW Inlet: 6" ANSI / JW Outlet: 5" Cat Flange

- AC Inlet: 6" ANSI / AC Outlet: 3-1/2" ANSI

-

Exhaust

- Dry exhaust manifold

- Bolted flange (ANSI 6" & DIN 150) with bellow for each turbo (Qty 4). 50 Hz

-

Fuel

- Filters x 3

- Secondary/tertiary fuel filters

- 4 Micron spin on type

- 10 Micron spin on type

- Engine mounted filters x 3

- Primary fuel filter water/fuel water separator

-

Generators and Attachments

- Salient pole

- RFI suppression

- Anti-condensation space heater

- IEC platinum Stator RTDs

- Form wound

- NEMA Class H insulation

- Voltage regulator

- Reactive droop capability

- Min/max Exciter limiter

- 3 Phase voltage sensing

- Exciter diode monitor

- 6 Leads

- 3 Phase brushless

- Right side extension box, bottom cable entry

- Permanent magnet excitation (PMG)

- Class H temperature rise at 40C ambient

-

Governing System

- ADEM A4

- Redundant shutdown (Overspeed protection through a duplicate speed sensing system)

-

Lube System

- Oil drain lines and valve

- Gear type lube oil pump

- Oil filter, filler and dipstick

- Integral lube Oil cooler

- Lubricating oil

- Fumes disposal

-

Mounting Systems

- Rails - Engine/Generator

- Rubber anti-vibration mounts - shipped loose

-

Starting / Charging System

- Batteries and battery rack w/cables

- Dual 24 volt electric starting motors

- Battery disconnect switch

-

General

- SAE standard rotation

- Right hand servicing

- Paint - Caterpillar yellow with high gloss black rails

Optional Equipment

-

Air Inlet Systems

- Single element air cleaner

-

Control Panels

- EMCP 4.4

- Controller and MV and HV power connection locations

- Load share module

- Controller voltage and current sensing groups

- Speed adjust

- Annunciator modules

- Customer interface options

- Generator temperature monitoring

- E-Stop

- Interconnect harness

- Generator harness

- Modbus monitoring of packages

- Vandal proof panel door

-

Cooling System

- Package mounted radiators

- Remote radiators

- Fuel cooler

-

Crankcase Systems

- Explosive relief valves

- Crankcase ventilation system

-

Exhaust System

- Front housing - Standby or mission critical

- Front housing - Prime or continuous

- Exhaust collectors/manifold

- Mufflers (15, 25 and 34 dBA)

-

Fuel System

- Primary fuel filter

-

Generators and Attachments

- Medium voltage - 3000 Frames - 50 Hz, 3 phase, 1500 rpm, FW, PM, No of leads=6, Pitch 0.6667

- Thermostat for space heater

- Generator air cleaner

- Differential current transformers - (5, 9 and 15 kV Class)

-

Instrumentation

- Pyrometer and thermocouples

-

Lube System

- Lube oil heater

- Lube oil heater with Crankcase explosion relief valves

- Drain group oil pans

- Lubricating oil

- Electric prelube pumps

- Oil filters

-

Mounting System

- Rubber anti-vibration mounts

- Spring type linear vibration isolators

- IBC vibration isolators - Shipped loose

-

Special Tests / Reports

- Generator test report

- PGS Test report @ 1.0 power factor

- PGS Test report @ 0.8 power factor

- Standard genset TVA (Torsional Vibration Analysis) report

- Custom generator TVA report

- Special test charge - Engine only

- Genset fuel consumption test

- Standard engine test charge

-

Starting / Charging System

- 24 Volt electric starting motor

- Air starting motor

- Air pressure regulator

- Starter location covers

- 24 Volt battery set - Dry

- 20, 35 and 50 Amp Battery chargers

- Charging alternators - Dry

- Jacket water heaters

-

General

- Special paint - 3500, Colors (other than Caterpillar yellow or high performance paints)

- US aid emblem

- Service tools

- Engine barring group

- Manual

- Engine barring air powered

- control GP - air powered bar group