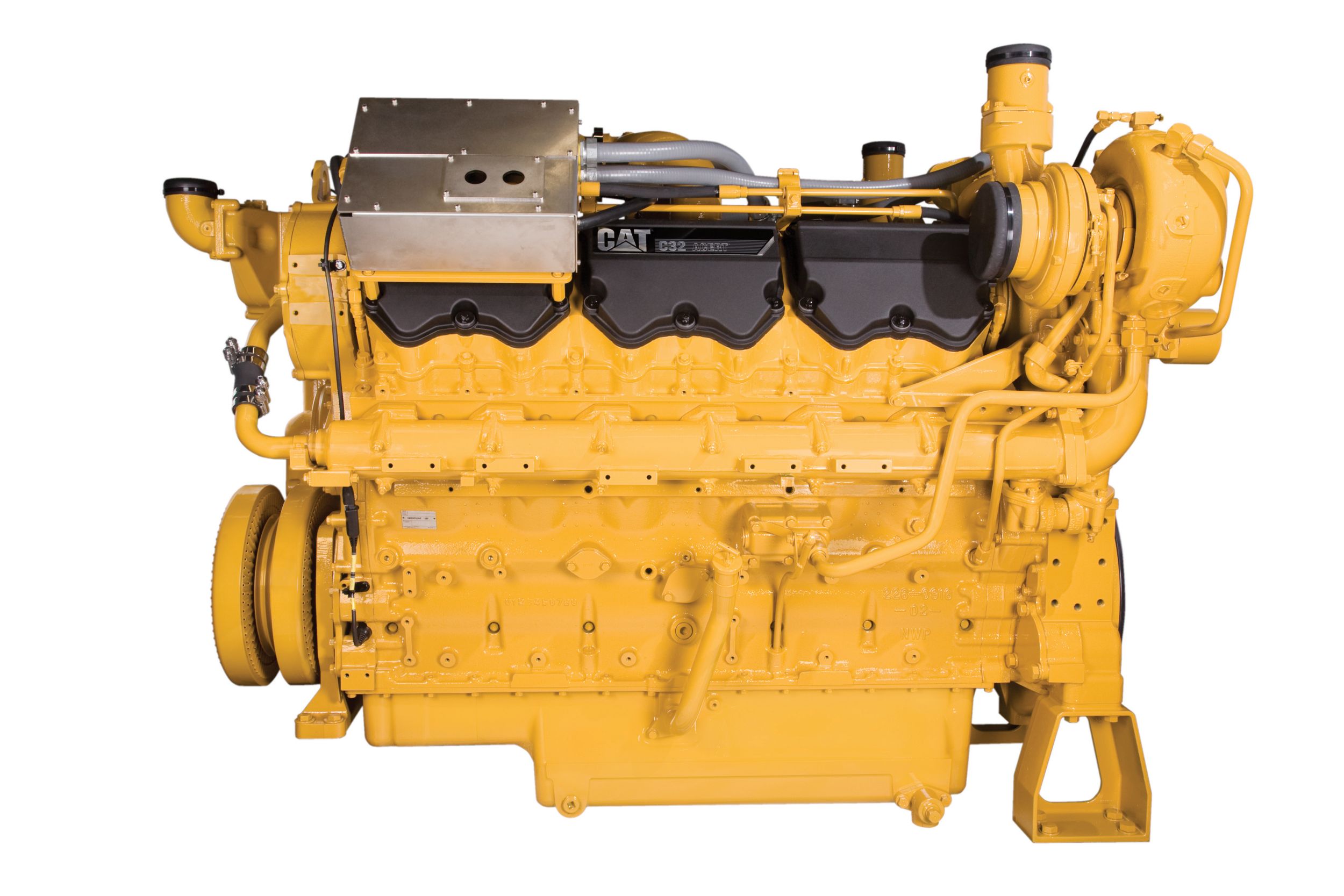

Technicial Specifications

| Maximum Rating | 1110 BHP 828 bkW |

| Displacement | 1960 in³ 32.1 l |

| Minimum Rating | 800 BHP 597 bkW |

| Aspiration | Turbocharged-Aftercooled Turbocharged-Aftercooled |

| Flywheel and Flywheel Housing | SAE No. 0 or SAE No. 1 SAE No. 0 or SAE No. 1 |

| Flywheel Teeth | 136 136 |

| Stroke | 6.4 in 162 mm |

| Bore | 5.7 in 145 mm |

| Emissions | U.S. Non-Road Tier 2 CARB, IMO Tier II, EPA Marine Tier 2 U.S. Non-Road Tier 2 CARB, IMO Tier II, EPA Marine Tier 2 |

| Length | 76.18 in 1934.9 mm |

| Width | 56.34 in 1431 mm |

| Height | 54.66 in 1388.3 mm |

| Weight | 6950 lb 3152 kg |

Advantages and Features

Technology

- Electrical harness containing point-to-point wiring without splices in any power/signal wires - Electrical harnesses and connectors are overmolded and are routed through urethane tube for protection against impact and vertical flame propagation. - To meet safety requirements, connectors require the use of a special tool to be disconnected and bear the “do not disconnect while energized” warning. - Optional ATEX and NEC certified 25-foot customer harness - ECU is certified as part of the engine to restricted breathing per EN 60079-15. ECU is protected with a stainless steel guard. - Fuel injector connections at valve cover bases are protected with stainless steel guardsAdvanced Digital Engine Management

ADEM A4 engine management system integrates speed control, air/fuel ratio control and ignition/detonation controls into a complete engine management system with integrated digital ignition, engine protection and monitoring.Transmissions

The full line of Cat engine/transmission packages can be fully integrated with your axle, hydraulics, and operator interface. Cat transmissions deliver continuous operation under full load, smooth shifting at any speed, and maximum up time, with unmatched durability and easy maintenance.Custom Packaging

Trust a Cat factory custom package to meet your exact petroleum application needs. Cat engines, generators, enclosures, controls, radiators, transmissions — anything your project requires — can be custom designed and matched to create a one-of-a kind solution. Custom packages are globally supported and are covered by a oneyear warranty after startup.Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging timeTesting

Every engine is full-load tested to ensure proper engine performance.Product Support Offered Through Global Cat Dealer

More than 2,200 dealer outlets Cat factory-trained dealer technicians service every aspect of your petroleum engine Cat parts and labor warranty Preventive maintenance agreements available for repairbefore-failure options S•O•S SM program matches your oil and coolant samples against Caterpillar set standardsOver 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.Standard Equipment

-

Air Inlet System

- Dual side-mounted turbochargers — inlet 152.4 mm (6 in) hose connection

-

Control System

- Programmable ratings

- Cold mode start strategy

- Automatic altitude compensation

- Power compensation for fuel temperature

- Programmable low and high idle

- Electronic diagnostics and fault logging

- Engine monitoring and protection system (speed, temperature, pressure)

- J1939 Broadcast (diagnostic, engine status and control)

- Electronic governing, PTO speed control

- Certified electrical control system

- Customer interface harness available as optional attachment

-

Cooling System

- Thermostats and housing — outlet LH vertical orientation

- Jacket water pump — gear-driven, centrifugal, RH

-

Exhaust System

- Exhaust manifold, water-cooled

- Dual turbo, rear turbo exhaust, full marmon connection 127 mm (5 in), maximum load 10 kg for direct connection to turbo

- Water-cooled center sections

-

Flywheels and Flywheel Housing

- Mandatory selection of: SAE No. 0 or SAE No. 1 flywheel and housing SAE standard rotation

-

Fuel System

- MEUI fuel system

- Fuel filter — RH (2 micron high performance)

- Fuel transfer pump

- Fuel priming pump

-

Lube System

- Crankcase breather — rear-mounted

- Oil cooler — RH

- Oil filler in RH front gear case

- Oil filter — RH

- Oil level gauge — RH

- Oil pan rear sump

-

Mounting System

- Narrow front support

-

Power Take-Offs

- Crankshaft pulley — 203.2 mm (8 in) 5 grooves 15.9 (.63 in) wide; 292.1 mm (11.5 in) 1 groove 15.9 (.63 in) wide

-

General

- Paint — Cat yellow

- Vibration damper with single pulley

- Lifting eyes

- Automatic variable timing — electronic

- Electronic installation kit 70-pin connector (connectors, pins, socket)

-

Mandatory Options

- HP must be specified when ordering

- All engines shipped at 2100 rpm

- Flywheel housing

- These engines meet the current IMO emission standards as defined by Regulation 13 of Annex VI to the International Convention for the Prevention of Pollution from Ships, 1973, as modified by the Protocol of 1978, further amended by the Protocol of 1997. A statement of compliance issued by the United States government's EPA (Environmental Protection Agency) is included in the technical file that is shipped with the engine as proof of our engine's ability to meet IMO emissions requirements. If this technical file is insufficient to meet the customer's requirements, then a GL or CCS IMO emissions certification may be ordered.

Optional Equipment

-

Air Inlet System

- Air cleaner

- Air inlet adapters

- Turbocharger outlet adapters

- Air lines

-

Charging System

- Battery chargers

- Charging alternators

- Alternator mounting

- Circuit breakers and mountings

-

Cooling System

- Dry charge coolant conditioners

- Thermostat housing

- Coolant level sensor

- Radiator

- Suction fans and blower fans

- Fan adapters

- Fan drives

-

Emissions

- IMO certifications

-

Exhaust System

- Elbows

- Mufflers

-

Fuel Systems

- Electric fuel priming pump

-

Instrumentation

- Customer management device

- Interconnect harness

- Gauges and instrument panels

-

Lube System

- Oil pans

- Oil service side

- Oil level gauge

- Oil filters

- Lubricating oils

-

Mounting System

- Structural steel base

- Engine support — front and rear

-

Power Take-Offs

- Auxiliary drive

- Damper pulley

- Hydraulics gear pumps

-

Protection System

- Mechanical shutoffs

- Solenoid shutoffs

-

Starting System

- Electric starting motors - 12V, 24V

- Battery sets - 24V

- Battery rack and cable

- Starting aids

-

Transmission Arrangement

- Transmission water lines

- Transmission cooler