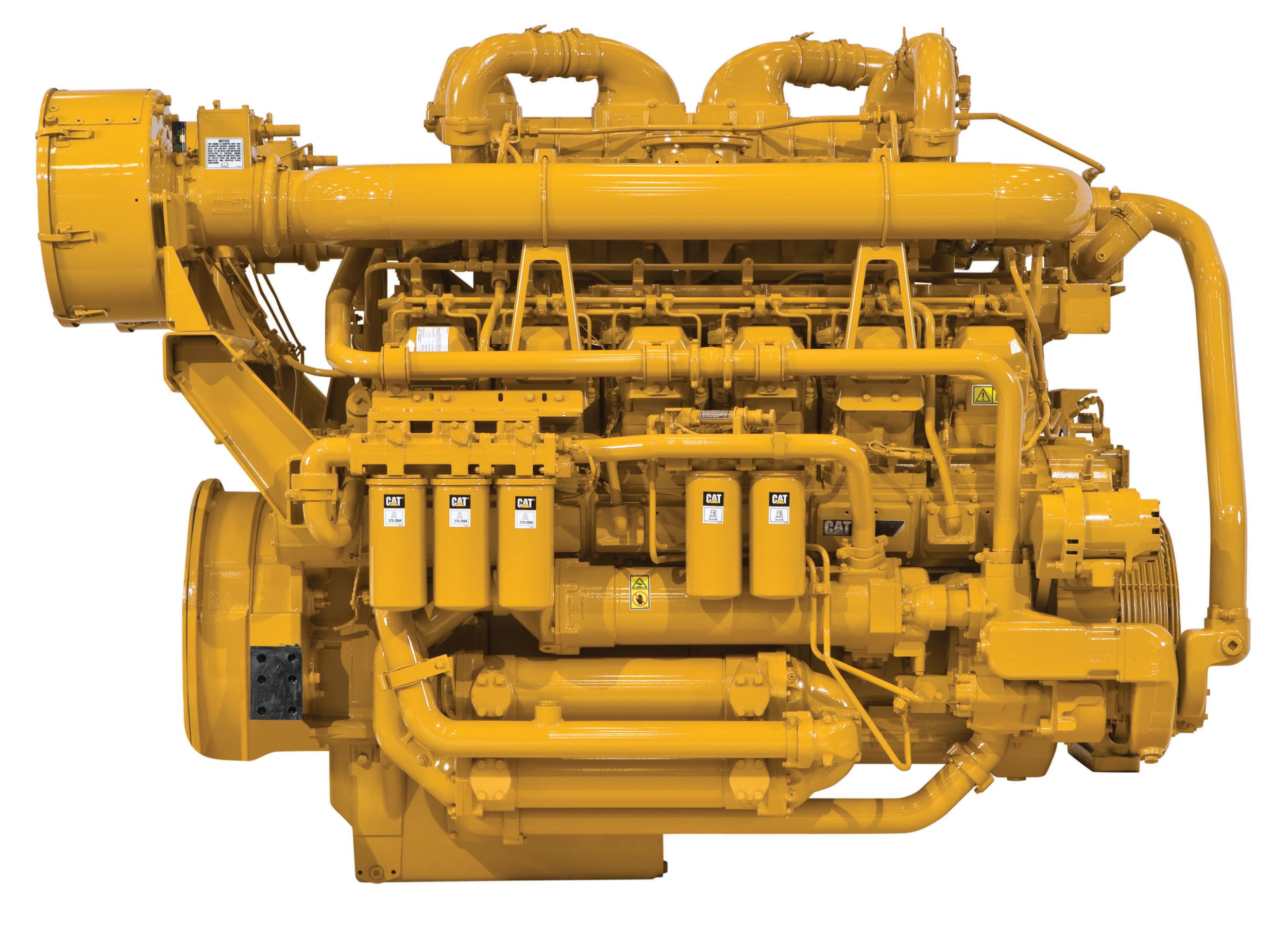

Technicial Specifications

| Maximum Power | 1500 hp 1120 kW |

| Maximum Torque | 5259 lb-ft @ 1500 rpm 7130 Nm @ 1500 rpm |

| Rated Speed | 1800 rpm 1800 rpm |

| Minimum Power | 1500 hp 1120 kW |

| Emissions | U.S. EPA Tier 2 Equivalent U.S. EPA Tier 2 Equivalent |

| Length | 120.8 in 3067 mm |

| Width | 70.3 in 1785 mm |

| Height | 71.1 in 1319 mm |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 13400 lb 6078 kg |

| Engine Configuration | V-12, 4-Stroke-Cycle Diesel V-12, 4-Stroke-Cycle Diesel |

| Bore | 6.7 in 170 mm |

| Stroke | 7.5 in 190 mm |

| Displacement | 3158 in³ 51.8 l |

| Aspiration | Turbocharged Aftercooled Turbocharged Aftercooled |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Aftertreatment | - - |

Advantages and Features

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.Quality

Every Cat engine is manufactured to stringent quality standards in order to assure customer satisfaction.World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Standard Equipment

-

Air Inlet System

- Air to Air Aftercooled (ATAAC)

- Two turbochargers, rear mounted

-

Control System

- Electronic Engine Control, RH

-

Cooling System

- Thermostats and housing

- Gear driven centrifugal jacket water pump

- Connections for radiator cooling

-

Exhaust System

- Exhaust manifold, dry

- Two turbochargers with watercooled bearings

- Two exhaust outlets, 203 mm (8 in) round flange

-

Flywheels and Flywheel Housing

- SAE No. 00 flywheel (183 teeth)

- SAE No. 00 flywheel housing

-

Fuel System

- Fuel filter, LH spin-on type

- Fuel transfer pump

- Electronically controlled unit injectors

-

Instrumentation

- No standard instrument or gauge panel

-

Lube System

- Crankcase breather, top mounted

- Oil cooler

- Oil filler and dipstick, LH

- Oil pump

- Oil filter, LH, spin-on type

- Oil pan

-

Mounting System

- Trunnion front support

-

Power Take Off

- Front housing, two sided

-

Protection System

- ECM monitoring system to provide customer programmable engine

- Deration strategies to protect against adverse operating conditions

- Emergency stop logic inputs provided at 40 pin customer interface connection

-

Starting System

- Dual 24V electric starting motor

-

General

- Vibration damper

- Lifting eyes

- Paint: Caterpillar yellow