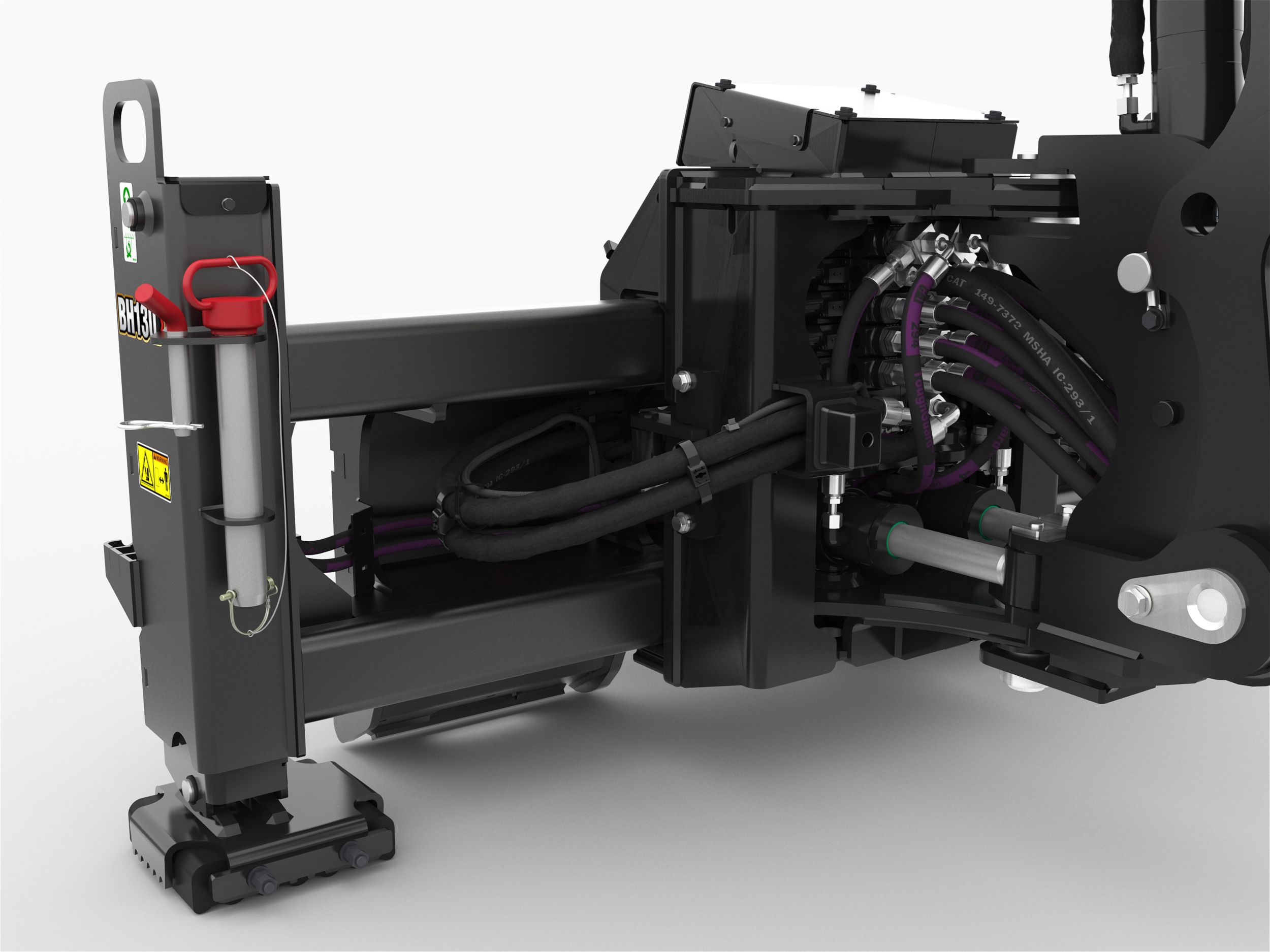

Technicial Specifications

| Maximum Digging Depth | 2972 mm |

| Operating Weight | 1055 kg |

| Overall Length | 2210 mm |

| Stabilizer Spread - Operating Position | 1813 mm |

| Digging Depth at 610 mm (2 ft) | 3156 mm |

| Digging Depth at 4220 mm (8 ft) | 2705 mm |

| Straight Wall Digging Depth | 2020 mm |

| Overall Operating Height | 3723 mm |

| Loading Height | 2470 mm |

| Loading Reach | 1869 mm |

| Reach From Swing Pivot at Ground Line | 4029 mm |

| Swing Arc | 180 degrees |

| Bucket Rotation | 183 degrees |

| Bucket Breakout Force | 3181 kg |

| Stick Breakout Force | 1605 kg |

| Boom Pivot Height | 448 mm |

| Ground Clearance | 99 mm |

| Transport Height | 2562 mm |

| Transport Width | 2041 mm |

| Required Hydraulics | Standard Flow |

| Optimal Hydraulic Flow | 50-86 L/min (13-23 gpm) |

| Optimal Hydraulic Pressure | 180-230 bar (2600-3340 psi) |

| Total Side Shift Travel | 838 mm |

| Interface Type | Skid Steer Coupler |