Technicial Specifications

| Maximum Power | 275 hp 205 kW |

| Maximum Torque | 774 lb-ft @ 1400 rpm 1050 Nm @ 1400 rpm |

| Rated Speed | 116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpm 116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpm |

| Minimum Power | 156 hp 116 kW |

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

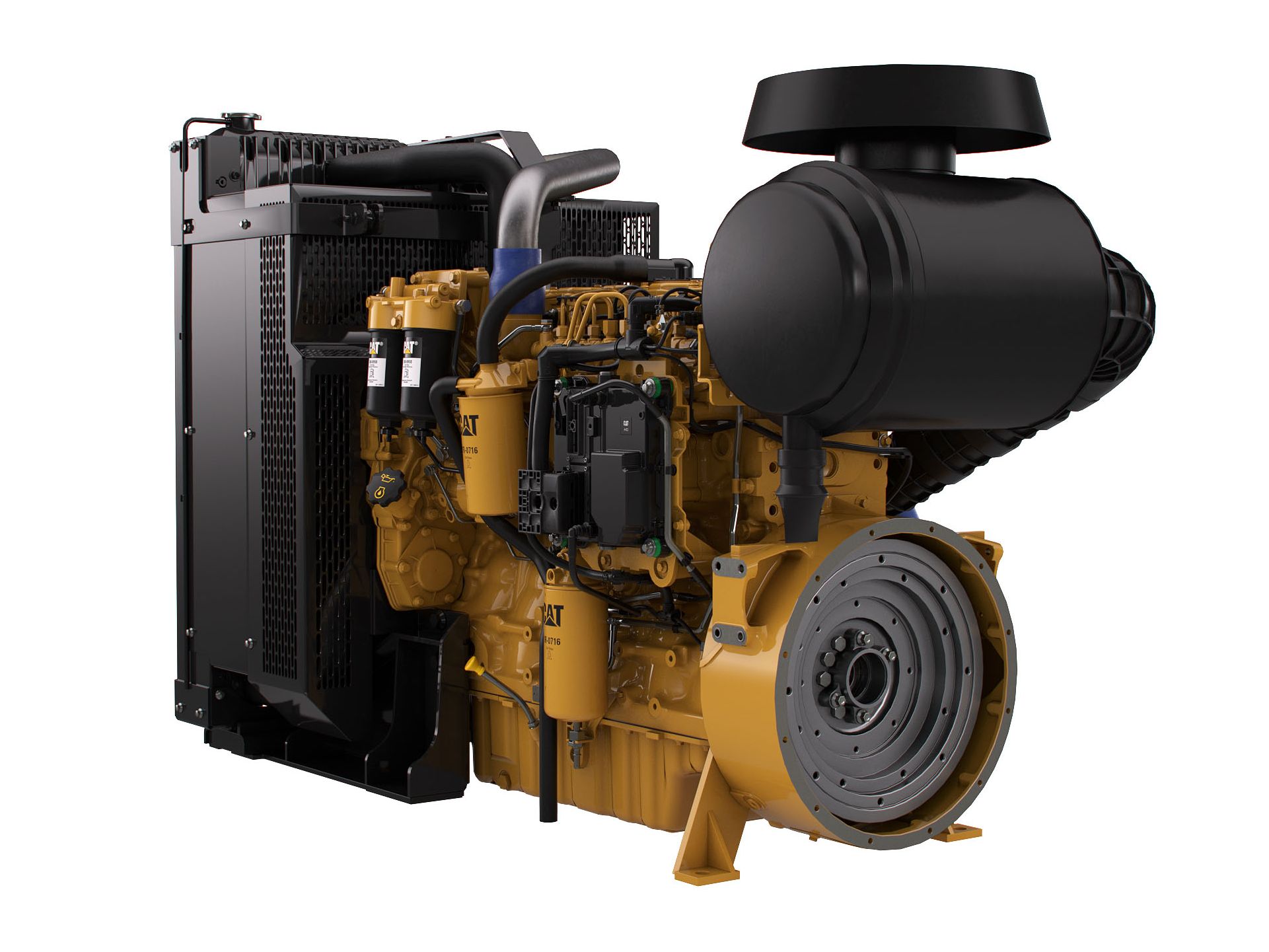

| Engine Configuration | Inline 6, 4-Stroke-Cycle Diesel Inline 6, 4-Stroke-Cycle Diesel |

| Bore | 4.1 in 105 mm |

| Stroke | 5.3 in 135 mm |

| Displacement | 427.7 in³ 7.01 l |

| Compression Ratio | 16.8:1 16.8:1 |

| Aspiration | Turbocharged Aftercooled (TA) Turbocharged Aftercooled (TA) |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Aftertreatment | - - |

| Length | 68 in 1728 mm |

| Width | 31 in 788 mm |

| Height | 44.8 in 1140 mm |

| Weight | 1737 lb 788 kg |

Advantages and Features

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.Broad Application Range

Industry leading range of factory configurable ratings and options for agricultural, material handling, construction, mining, aircraft ground support, and other industrial applications.Package Size

Exceptional power density enables standardization across numerous applications. Multiple installation options minimize total package size. Ideal for equipment with narrow engine compartments.World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOS℠ sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Standard Equipment

-

Air Inlet

- Standard air cleaners

-

Control System

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

-

Cooling System

- Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

- 50:50 water glycol mix

- Cooling system designed for operation in 48 C (118 F) ambient.

-

Flywheels and Flywheel Housing

- Wide choice of drivetrain interfaces, including SAE No. 1, SAE No. 2, and SAE No. 3 configurations

-

Fuel System

- Electronic high pressure common rail

- ACERT Technology

- Innovative filter design to ensure maximum protection of the engine

-

Lube System

- Wide choice of sumps for different applications

-

Power Take Off

- SAE A or SAE B flanges on left-hand side. Right-hand side twin PTO also available. Engine power can also be taken from the front of the engine on some applications.

-

General

- Paint: Caterpillar yellow